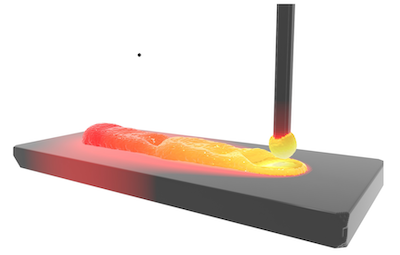

Simulation of wire metal transfer in the cold metal transfer (CMT) variant of gas metal arc welding using the smoothed particle hydrodynamics (SPH) approach

Cold metal transfer (CMT) is a variant of gas metal arc welding (GMAW) in which the molten metal of the wire is transferred to the weld pool mainly in the short-circuit phase. A special feature here is that the wire is retracted during this strongly controlled welding process. This allows precise and spatter-free formation of the weld seams with lower energy input. To simulate this process, a model based on the particle-based smoothed particle hydrodynamics (SPH) method is developed. This method provides a native solution for the mass and heat transfer. A simplified surrogate model was implemented as an arc heat source for welding simulation. This welding simulation model based on smoothed particle hydrodynamics method was augmented with surface effects, the Joule heating of the wire, and the effect of the electromagnetic forces. The model of metal transfer in the cold metal transfer process shows good qualitative agreement with real experiments.

@article{MWW+24,

author = {Mokrov, O. and Warkentin, S. and Westhofen, L. and Jeske, S. and Bender, J. and Sharma, R. and Reisgen, U.},

title = {Simulation of wire metal transfer in the cold metal transfer (CMT) variant of gas metal arc welding using the smoothed particle hydrodynamics (SPH) approach},

journal = {Materialwissenschaft und Werkstofftechnik},

volume = {55},

number = {1},

pages = {62-71},

keywords = {cold metal transfer (CMT), free surface deformation, gas metal arc welding (GMAW), simulation, smoothed particle hydrodynamics (SPH), geglätteter Partikel-basierter hydrodynamischer Ansatz (SPH), Kaltmetalltransfer (CMT), Metallschutzgasschweißens, Oberflächenverformung, Simulation},

doi = {https://doi.org/10.1002/mawe.202300166},

year = {2024}

}