Publications

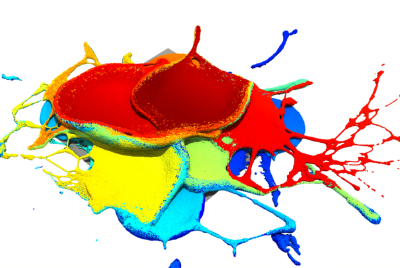

Modeling the Droplet Impact on the Substrate with Surface Preparation in Thermal Spraying with SPH

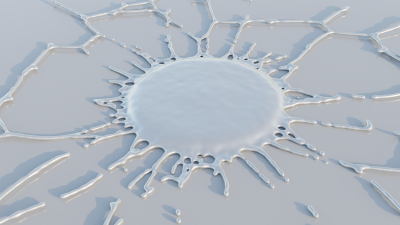

The properties of thermally sprayed coatings depend heavily on their microstructure. The microstructure is determined by the dynamics of the impact of the droplets on the substrate surface and the subsequent overlapping of the previously solidified and deformed droplets. Substrate preparation prior to spraying ensures strong adhesion of the coating. This includes roughening and preheating of the substrate surface. In the present study, the smoothed particle hydrodynamics (SPH) method is used to model the Al2O3 impact on a preheated substrate and a roughened substrate surface. A semi-implicit enthalpy–porosity method is applied to simulate the solidification process in the mushy zone. In addition, an implicit correction for SPH simulations is used to improve the performance and stability of the simulation. To investigate the dynamics of heat transfer in the contact between the surface and the droplet, the discretization of the substrate is also taken into account. The results show that the studied substrate surface conditions affect the splat morphology and the solidification process. Subsequently, the simulation of multiple droplets for coating formation is also performed and analyzed.

@Article{BHJ+23,

author = {Kirsten Bobzin and Hendrik Heinemann and Kevin Jasutyn and Stefan Rhys Jeske and Jan Bender and Sergej Warkentin and Oleg Mokrov and Rahul Sharma and Uwe Reisgen},

journal = {Journal of Thermal Spray Technology},

title = {Modeling the Droplet Impact on the Substrate with Surface Preparation in Thermal Spraying with SPH},

year = {2023},

month = {jan},

doi = {10.1007/s11666-023-01534-0},

}

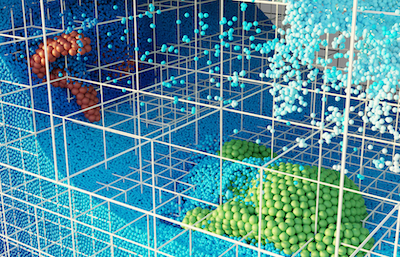

Fast Octree Neighborhood Search for SPH Simulations

We present a new octree-based neighborhood search method for SPH simulation. A speedup of up to 1.9x is observed in comparison to state-of-the-art methods which rely on uniform grids. While our method focuses on maximizing performance in fixed-radius SPH simulations, we show that it can also be used in scenarios where the particle support radius is not constant thanks to the adaptive nature of the octree acceleration structure.

Neighborhood search methods typically consist of an acceleration structure that prunes the space of possible particle neighbor pairs, followed by direct distance comparisons between the remaining particle pairs. Previous works have focused on minimizing the number of comparisons. However, in an effort to minimize the actual computation time, we find that distance comparisons exhibit very high throughput on modern CPUs. By permitting more comparisons than strictly necessary, the time spent on preparing and searching the acceleration structure can be reduced, yielding a net positive speedup. The choice of an octree acceleration structure, instead of the uniform grid typically used in fixed-radius methods, ensures balanced computational tasks. This benefits both parallelism and provides consistently high computational intensity for the distance comparisons. We present a detailed account of high-level considerations that, together with low-level decisions, enable high throughput for performance-critical parts of the algorithm.

Finally, we demonstrate the high performance of our algorithm on a number of large-scale fixed-radius SPH benchmarks and show in experiments with a support radius ratio up to 3 that our method is also effective in multi-resolution SPH simulations.

@ARTICLE{ FWL+22,

author= {Jos{\'{e}} Antonio Fern{\'{a}}ndez-Fern{\'{a}}ndez and Lukas Westhofen and Fabian L{\"{o}}schner and Stefan Rhys Jeske and Andreas Longva and Jan Bender },

title= {{Fast Octree Neighborhood Search for SPH Simulations}},

year= {2022},

journal= {ACM Transactions on Graphics (SIGGRAPH Asia)},

publisher= {ACM},

volume = {41},

number = {6},

pages= {13}

}

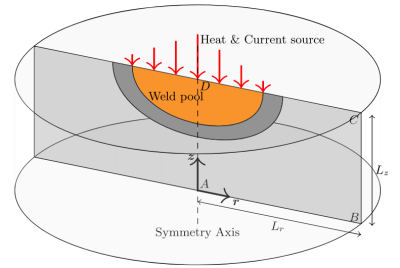

Quantitative Evaluation of SPH in TIG Spot Welding

While the application of the Smoothed Particle Hydrodynamics (SPH) method for the modeling of welding processes has become increasingly popular in recent years, little is yet known about the quantitative predictive capability of this method. We propose a novel SPH model for the simulation of the tungsten inert gas (TIG) spot welding process and conduct a thorough comparison between our SPH implementation and two Finite Element Method (FEM) based models. In order to be able to quantitatively compare the results of our SPH simulation method with grid based methods we additionally propose an improved particle to grid interpolation method based on linear least-squares with an optional hole-filling pass which accounts for missing particles. We show that SPH is able to yield excellent results, especially given the observed deviations between the investigated FEM methods and as such, we validate the accuracy of the method for an industrially relevant engineering application.

@Article{JSS+22,

author = {Stefan Rhys Jeske and Marek Sebastian Simon and Oleksii Semenov and Jan Kruska and Oleg Mokrov and Rahul Sharma and Uwe Reisgen and Jan Bender},

journal = {Computational Particle Mechanics},

title = {Quantitative evaluation of {SPH} in {TIG} spot welding},

year = {2022},

month = {apr},

doi = {10.1007/s40571-022-00465-x},

publisher = {Springer Science and Business Media {LLC}},

}

Application and Benchmark of SPH for Modeling the Impact in Thermal Spraying

The properties of a thermally sprayed coating, such as its durability or thermal conductivity depend on its microstructure, which is in turn directly related to the particle impact process. To simulate this process we present a 3D Smoothed Particle Hydrodynamics (SPH) model, which represents the molten droplet as an incompressible fluid, while a semi-implicit Enthalpy-Porosity method is applied for modeling the phase change during solidification. In addition, we present an implicit correction for SPH simulations, based on well known approaches, from which we can observe improved performance and simulation stability. We apply our SPH method to the impact and solidification of Al2O3 droplets onto a substrate and perform a comprehensive quantitative comparison of our method with the commercial software Ansys Fluent using the Volume of Fluid (VOF) approach, while taking identical physical effects into consideration. The results are evaluated in depth and we discuss the applicability of either method for the simulation of thermal spray deposition. We also evaluate the droplet spread factor given varying initial droplet diameters and compare these results with an analytic expression from previous literature. We show that SPH is an excellent method for solving this free surface problem accurately and efficiently.

@Article{JBB+22,

author = {Stefan Rhys Jeske and Jan Bender and Kirsten Bobzin and Hendrik Heinemann and Kevin Jasutyn and Marek Simon and Oleg Mokrov and Rahul Sharma and Uwe Reisgen},

journal = {Computational Particle Mechanics},

title = {Application and benchmark of {SPH} for modeling the impact in thermal spraying},

year = {2022},

month = {jan},

doi = {10.1007/s40571-022-00459-9},

publisher = {Springer Science and Business Media {LLC}},

}