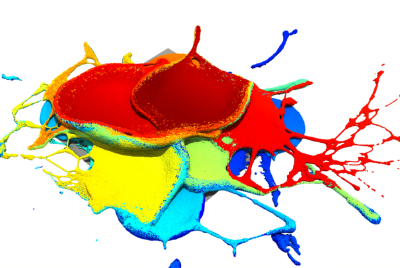

Modeling the Droplet Impact on the Substrate with Surface Preparation in Thermal Spraying with SPH

The properties of thermally sprayed coatings depend heavily on their microstructure. The microstructure is determined by the dynamics of the impact of the droplets on the substrate surface and the subsequent overlapping of the previously solidified and deformed droplets. Substrate preparation prior to spraying ensures strong adhesion of the coating. This includes roughening and preheating of the substrate surface. In the present study, the smoothed particle hydrodynamics (SPH) method is used to model the Al2O3 impact on a preheated substrate and a roughened substrate surface. A semi-implicit enthalpy–porosity method is applied to simulate the solidification process in the mushy zone. In addition, an implicit correction for SPH simulations is used to improve the performance and stability of the simulation. To investigate the dynamics of heat transfer in the contact between the surface and the droplet, the discretization of the substrate is also taken into account. The results show that the studied substrate surface conditions affect the splat morphology and the solidification process. Subsequently, the simulation of multiple droplets for coating formation is also performed and analyzed.

@Article{BHJ+23,

author = {Kirsten Bobzin and Hendrik Heinemann and Kevin Jasutyn and Stefan Rhys Jeske and Jan Bender and Sergej Warkentin and Oleg Mokrov and Rahul Sharma and Uwe Reisgen},

journal = {Journal of Thermal Spray Technology},

title = {Modeling the Droplet Impact on the Substrate with Surface Preparation in Thermal Spraying with SPH},

year = {2023},

month = {jan},

doi = {10.1007/s11666-023-01534-0},

}